Start: To define.

DESCRIPTION:

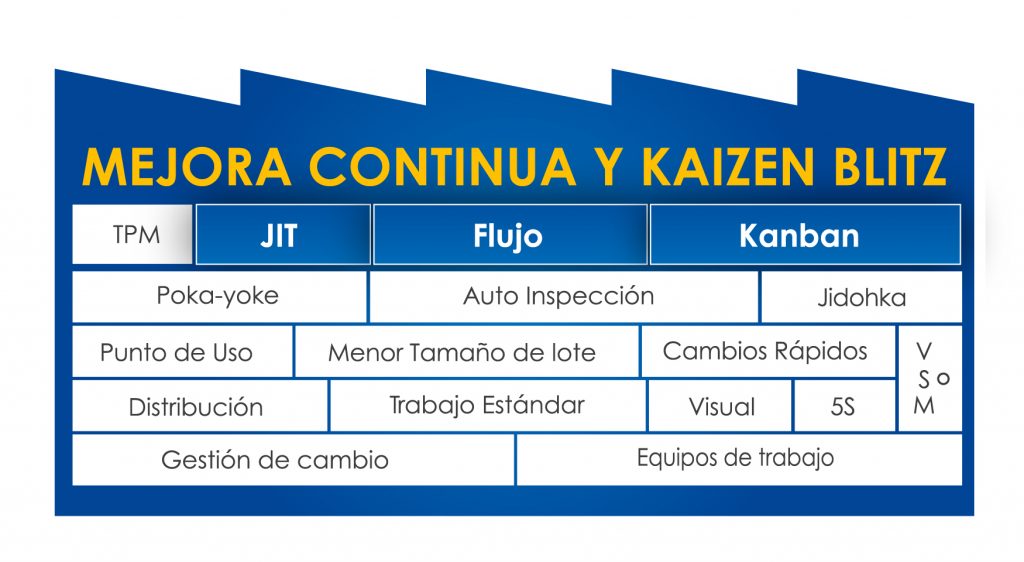

The Lean Operations Design Workshop shows how to evolve Lean transformation from an isolated improvement approach to transforming plant production systems by implementing a Lean production control system.

The course will develop step by step the stages to implement continuous flow, level production and pull.

GOALS:

At the end of the training, participants will be able to develop a Lean production control system.

CONTENTS:

INTRODUCTION – PRODUCE FOR THE TAKT

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

MONITORING 1 – CONTINUOUS FLOW

- Takt analysis review.

- Continuous flow.

- Suitable products.

- Identification of work elements.

- Automation Levels.

- Distribution of Physical Space.

- Calculation of Operators.

- Cell Design.

CONTINUOUS FLOW WORKSHOP

- Collection of the information necessary for the analysis.

- Paper Kaizen.

- Implementation Gemba walks.

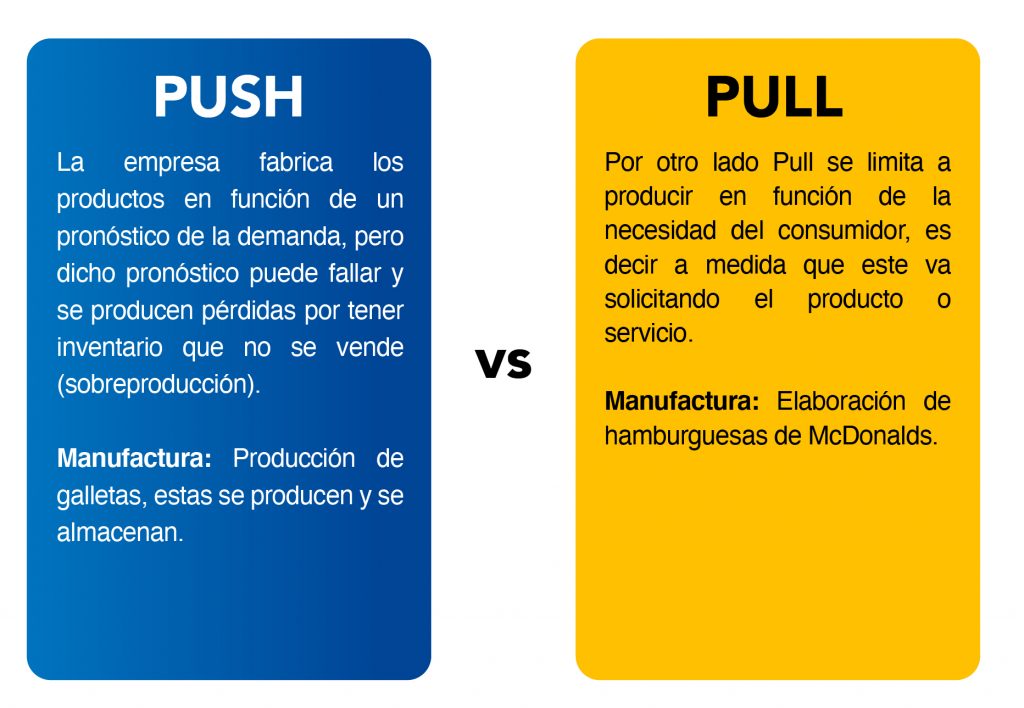

TRACKING 2 – PULL

- Gemba Walks to Review Implementation Progress.

- Construction of Supermarkets.

1- ABC of products.

2- Supermarket size calculation.

3- Supermarket Organization.

PULL WORKSHOP

- Collection of information for construction of supermarkets.

- Paper Kaizen.

- Implementation Gemba Walks.

FOLLOW-UP 3 – PACEMAKER

- Pull Implementation Progress Review Gemba Walks.

- Pacemaker.

- Where to program the value chain?

- How to level production?

- How to level the pacemaker?

- How to transfer the demand to the step-by-step process?

PACEMAKER WORKSHOP

- Collection of information for definition of pacemaker

Paper Kaizen.

Pacemaker Implementation Gemba Walk.

FOLLOW UP 4 – HEIJUNKA

- Pacemaker implementation progress review gemba walks.

- Heijunka.

- Pitch.

- Construction of the Heijunka.

HEIJUNKA WORKSHOP

- Collection of information for definition of hejunka.

- Paper Kaizen.

- Heijunka Implementation Gemba Walk.

MONITORING 5 – UP CHAIN PROCESSES

- Heijunka Implementation Progress Review Gemba Walks.

- Batch processes.

- Production Control in processes upstream of the Pacemaker.

- Production control of processes in batches upstream of the pacemaker.

UP CHAIN PROCESSES WORKSHOP

- Collection of information to define upstream processes

- Paper Kaizen

- Upstream Process Implementation Gemba Walk